Cofragem Concreto PVC PP Plastic Board Custom Concrete Forms

Description

Basic Info.

| Model NO. | BZ-PP |

| Material | PP |

| Forming Way | Extrusion |

| Application | Functional Components |

| Material Properties | High Impact |

| Markets Served | Building & Construction |

| Customized | Non-Customized |

| Usage | Exterior |

| Color | Single Color |

| Surface Finishing | Finished |

| Reusable Times | 50 Times |

| Advantage | Waterproof and Lightweight |

| Thickness | 12-21mm |

| Certificate | ISO9001:2015 |

| Transport Package | Pallets |

| Specification | 1220*2440mm/915*1830mm |

| Trademark | Beizhu |

| Origin | China |

| HS Code | 3925900000 |

| Production Capacity | 1000 PCS/Day |

Packaging & Delivery

Package Size 100.00cm * 100.00cm * 100.00cm Package Gross Weight 1400.000kgProduct Description

Product DescriptionProduct Specification

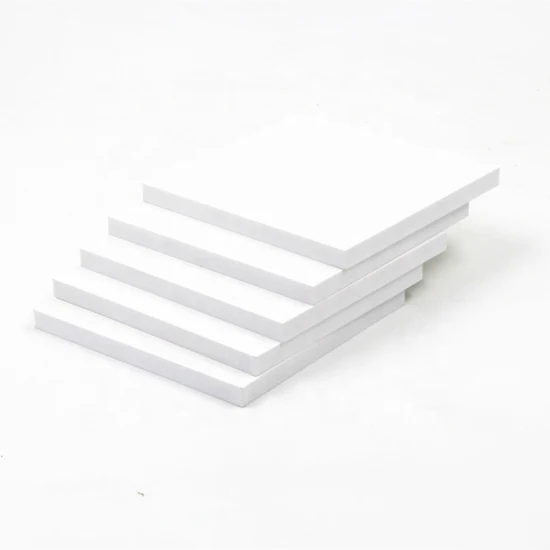

| STANDARD SIZE | THICKNESS | WEIGHT/PC | QTY/20FT | QTY/40HQ |

| 2440*1220MM | 12 MM | 21 KGS | 560 PCS | 1260 PCS |

| 2440*1220MM | 15 MM | 24 KGS | 450 PCS | 1026 PCS |

| 2440*1220MM | 18 MM | 28 KGS | 400 PCS | 900 PCS |

| 2440*1220MM | 20 MM | 30 KGS | 250 PCS | 800 PCS |

Cutting and customized size are available.

Product Advantages

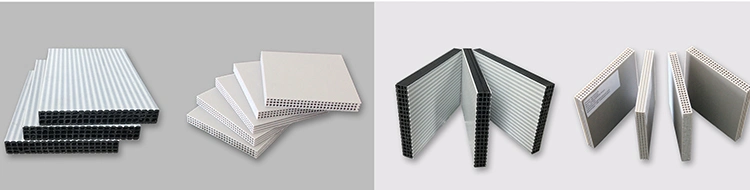

1. Durable, the reusable time can reach more than 60 times, long service life.2. No absorption of moisture, no deformation, no mildew; Long-term immersion stratification in the water,no bubbles, sheet size stability, especially suitable for underground and damp environment.3. Demould easily. No need brushing release agent, only tapping, the formwork will fall off. Shorten workinghours and speed up the construction schedule efficiently.4. Easy to process. Sawing, drilling and nailing are all available. Formworks can be combined vertically and horizontally optionally.5. Light weight, high strength, high hardness, impact resistance, wear resistance.

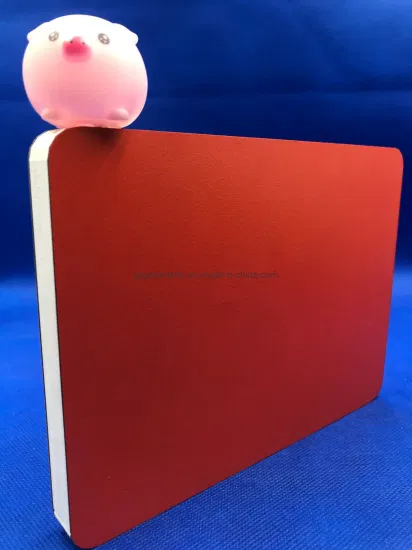

6. Surface is smooth, bright and clean; concreting and forming effect is good.

7. Good toughness. It could be used as cambered special-shaped formwork.

8. Acid and alkali resistance, corrosion resistance; Very suitable for the engineeringapplication in

coastal areas, mine, as well as seawall. It is need not do any preservative treatment both in using andstoring the formwork, which do not pollute the concrete surface.

9. Waste products can be recycled and reprocessed, making full use of waste materials. This property can greatly reduce the project cost compared with wooden formwork and bamboo formwork.

10. Environmental protection and energy saving, no pollution. No any poisonous or harmful gas.

11. Easy to remove. Removing is convenient, quick and safe, and the supporting is also easy to operate,advantageous to the organization construction, effectively improving the construction schedule.

Product Application

Product Using Feedback

Company Profile

Beizhu Plastic Formwork Company

Beizhu Plastic Formwork Company was founded in 2008, is located in Suqian City,which is one of thelargest manufacturers of construction plastic formwork in China. Beizhu has production area about 12000square meters, 5 production lines and 100 workers.

The construction plastic formwork has been exported to Finland, Canada, Australia, Russia, Ukraine, KenyaThailand, Korea and so on. Now Beizhu has 2 agents in Turkey and Thailand.

In 2013 year,Beizhu adopted the Certificate of ISO9001:2008 International Quality Management System. Beizhu keeps long-term cooperation with all the customers all over the world.

Prev: Jinbao 4*8 3mm 5mm White Artificial Kitchen Cabinet PVC Form Board

Next: Jinbao 1220*2440*3mm White Celuca Colored Plastic UV PVC Form Board

Our Contact